Some kitchen bench photos.

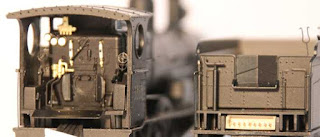

Phil came up tonight and we made a list of the corrections to the 3265 sample. These photos show the three locos together. The colour of 3265 looks great in the flesh, but is entirely wrong under the kitchen bench downlights. Never mind, just look at that lovely etched nameplate, and the lining of the headlight and compressor. 3333 is also shown with 3298's six-wheel tender, just to show the 'look' of that variation.

We also paid the bill tonight for the purchase all the components for the production run, so one step closer again to delivery.

The corrections we found are only minor things, and will not delay manufacture. Fascinatingly, we discovered that the cab numbers on 3265 are in different places on each side, in order to line up between the lines of rivets. So the final model will reflect this.

The buffers and rods are not blackened because this will only be done 'in bulk' on the final components. We are very happy now with the appearance of the front buffer beam with its removable piece for fitting a Kadee, and also with the unobtrusiveness of the join in the funnel. The cutout on the inside front of the cylinders, made to negotiate an 18" radius curve, is virtually invisible in any normal viewing situation, which is pleasing. Enjoy!