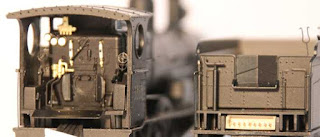

We have received the first two decoration samples of the 32 class. These contained a number of issues, quite a few of which were caused by the shipping (as the final protective packaging is not yet available) and some which require assembly tweaks in the production run. For example, the rods are not blackened as this needs to be outsourced, and is only set up to be done to all 3200 pieces, not to just 4! We are also awaiting the delivery of the sample of 3265 later this month, delayed due to the postal service losing the paint sample sent in November.

Our Technical Director Phil Badger has gone over the samples, and sent back an extensive list of amendments and corrections, so please don't let us know of things you can see. The photos are, however, a good representation of the liveries, and the appearance of the two footplate variations of the locos at this stage in the manufacturing process.

Phil reports that the running is smooth and quiet, with slightly-better-than-prototypical load hauling capabilities. He would like to emphasise, however, that the locos have been designed for a minimum of 24" (600mm) radius curves. The factory has experienced some derailments of the front bogie on 18" radius curves due to the bogie contacting the brake shoes of the front driving wheel. Where purchasers are requiring the loco to traverse an 18" (450mm) radius curve, this can probably be achieved by either the removal of the brake shoes, or the substitution of scale 3' diameter wheels in the bogie.

Looks great!

ReplyDeleteLooks great!

ReplyDelete